Graphene Coating Manufacturer Supplier

- Home

- Graphene Coating Manufacturer Supplier

graphene coating for sale

1.Graphene Waterborne Heat Dissipation Coating(Heat dissipation in metal substrates)

2.Graphene Waterborne Heavy-duty Anti-Corrosion Coating(Port Machinery, Bridges, Automotive Car)

Graphene raw material:Graphene powder,Graphene oxide, monolayer graphene, multilayer graphene, physically exfoliated graphene, graphene slurry.etc

Graphene applied product: graphene coating,graphene sheet,graphene masterbatch,graphene film .etc

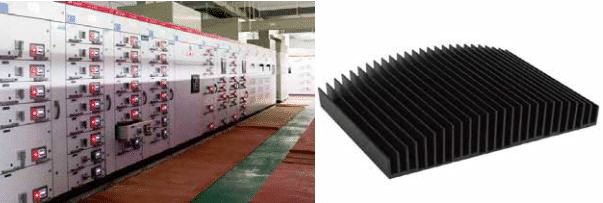

1.Graphene Coating Waterborne Heat Dissipation Coating Factory Sale

This product is composed of water-based two-component epoxy resin, additives, thermal conductivity paste, modified graphene, water, etc., and the supporting curing agent at room temperature or low temperature curing crosslinked film. The coating is smooth, and has good high temperature resistance. It is suitable

for heat dissipation coating of metal substrate.

More Data and Free Samples Please Contact Us

This data is derived from laboratory tests. No false labeling.

Construction process

1, Substrate treatment.

Before spraying the product ensure that the substrate or the previous coating surface is without oil, rust, and water, oil, rust, and water will be water-based paint adhesion and rust performance.

2, Diluent.

Deionized water or distilled water, such as unconditional, then take the local clean tap water testing pH, if the pH is neutral that is 7.0 can be used in the local clean tap water.

3, two-component preparation.

1) Mass ratio A:B = 3:1; construction of 10% to 30% water.

Before preparation, A, and B components need to be fully mixed, according to the needs of the site plus water to adjust the construction viscosity, the amount of water is 10% ~ 30%, and the construction viscosity is recommended to adjust to 10 ~ 20s spraying.

Adjust the construction viscosity to 10~20s spraying (construction viscosity can be adjusted to the best according to the conditions of the spray gun used, the rhythm of construction, the appearance of the sprayed effect, and other factors).

2) After adding hardener and water, mix thoroughly and filter with 50 mesh filter cloth to spray immediately.

3) Construction time limit: add curing agent two-component primer construction time limit of 4 hours, 4 hours to be used up, modulation of paint modulation within 4 hours of the dosage should not be too much to avoid waste.

4, Painting environmental requirements.

Ideal temperature and humidity requirements for the 20 ~ 70% relative humidity 15 ~ 30 °C. If the actual situation can not be achieved, after the line of the paint, the paint should be used in the environment if the actual situation can not be achieved, online test evaluation can be used without problems.

5, Painting method

1) Manual air spraying, high-pressure airless mixing, electrostatic spraying, and brushing can be used.

2) Rework: After the coating dries, use sandpaper to partially sand, then re-coat, no need to sand the whole piece.

3) Substrate temperature requirements: room temperature or has been low-temperature baking pieces (10 ~ 50 ° C) can be.

6, Cleaning.

1)The coating that has not dried and cured can be washed off immediately with water; 2)If the coating has been cured, it can be washed off immediately with water.

2) If the coating residue has been cured crosslinking can be used as a special matching cleaning agent to clean thoroughly.

Note: After each construction cycle, the pipeline of spraying equipment and spray gun should be cleaned thoroughly in time, so as not to clog the equipment after the paint is cured.

Performance Characteristics

1, less volatile solvents, clean flavor and environmental protection, non-flammable and non-explosive.

2、High crosslinking density, high-temperature resistance (up to 180°C).

3, graphene and thermal conductive paste composite heat dissipation system, good heat dissipation performance.

4, low viscosity, water as a diluent, suitable for a variety of construction methods.

5、Excellent water and solvent resistance.

Graphene Coating Storage

0 ~ 40 ℃, sealed storage in a cool place, since the date of production, the effective storage period of six months. Products exceeding the shelf life can be used after inspection and confirmation, if qualified.

2.Graphene Coating Waterborne Heavy-duty Anti-corrosion Coating Factory Sale

This product is composed of graphene water-based epoxy zinc-rich base coating, graphene water-based epoxy medium coating, and graphene water-based polyurethane top coating series, each coating is composed of water-based resin, additives, anti-rust fillers, modified graphene, water, etc., and supporting curing agent baking curing crosslinked film at room temperature or low temperature. The coating is smooth and smooth and has good high-temperature resistance. It is suitable for heavy anticorrosive coating of construction steel structures, bridges, port machinery, chemical storage tanks, oil pipelines, automotive Cars and other engineering fields.

Performance Characteristics

1. Less volatile solvent, net taste, and environmental protection, non-flammable and non-explosive;

2, high crosslinking density, high-temperature resistance ( up to 180 ℃);3, graphene and heat-conducting paste composite heat dissipation system, good heat dissipation performance;

4, low viscosity, water as diluent, suitable for a variety of construction methods;

5, with excellent water resistance, solvent resistance;

Graphene Coating Storage

0 ~ 40 ℃, sealed storage in a cool place, since the date of production, the effective storage period of six months. Products exceeding the shelf life can be used after inspection and confirmation, if qualified.

More Data and Free Samples Please Contact Us

Graphene Coating Costruction process

1, Substrate treatment:

Before spraying the product, ensure that there is no oil, no rust, and no water on the surface of the substrate or the first coat. Oil, rust, and water will all affect the adhesion and anti-rust properties of the water-based paint.

2. Diluent:

Deionized water or distilled water, if unconditional, take the local clean tap water to test the PH value, if the PH is neutral that is 7.0, you can use the local clean tap water.

3. Preparation of two components:

1) Graphene water-based epoxy zinc-rich substrate: mass ratio of component A: Component B =1:3; Construction water 2%~10%.

Graphene water-based epoxy medium coating: mass ratio of component A: Component B =7:10; Construction water 5%~20%.

Graphene waterborne polyurethane coating: mass ratio of Component A: Component B =4:1; Construction water 2%~10%.

The two-component coating needs to be fully stirred before preparation, according to the site

construction needs to add water to adjust the viscosity, add water in 2 %~10%, the construction viscosity is recommended to be adjusted to 20 ~30s for spraying ( the construction viscosity can

be adjusted to the best according to the spray gun mode l used, construction progress, the

appearance effect after spraying a nd other factors);

2) After adding the curing agent and water, stir fully, and spray immediately after filtering with 200 mesh filter cloth;

3) Construction time limit: the construction aging of the two-component primer with curing agent is 4 hours, which must be used up within 4 hours, and the amount of paint mixing within 4 hours should not be too much to avoid waste.

4, painting environment requirements:

The ideal temperature and humidity requirements are 20~70% relative humidity,15~30 ℃. If the actual situation can not be reached, after the field test evaluation no problem can be used.

5. Painting method:

1) Manual air spraying, high-pressure airless gas mixing, electrostatic spraying, and brush coating can be;

2) Rework: after the coating is dry, use sandpaper to grind it locally, then it can be re-painted without grinding the whole piece;

3) Base material temperature requirements: room temperature or has been baked at low temperature (10~50 ℃) can be.

6. Cleaning:

1) The coating that is not dried and solidified can be cleaned immediately with water;

2) If the coating residue has been cured and cross-linked, it can be thoroughly cleaned with a special matching cleaning agent.

Note: After each construction period, the pipeline and spray gun of the spraying equipment should be

thoroughly cleaned in time to avoid clogging the equipment after the coating curing. Avoid using

solvent-based diluent when cleaning the pipeline to cause water-based paint pollution.

About Us

Clean Concept Technology Limited, is engaged in exporting graphene raw materials(graphene powder, paste, coating, sheet) and graphene-applied products, such as graphene floor heating, graphene insulation panels, graphene thermal management materials, graphene electric blankets, and other graphene application products. Our factory covers 55,000 square meters in Shanghai, Jiangsu (Passed ISO9001, 14001, and 45001 management system certification), and our headquarters Levson Group was established in 2005. Now, our factory products are supplied to world-famous companies. We have received favorable comments from customers from all over the world. More

Our Invention Patent Display

| Certificate Name | Part of the core patent name | Patent No. |

| China Invention Patent | A method of preparing graphene by combining ultrasonic stripping and jet stripping | ZL 201610296912.7 |

| China Invention Patent | A method and equipment for the preparation of graphene using disk type flow milling | ZL 201610388138.2 |

| China Invention Patent | A graphene preparation method based on phenolphthalein | 201010207591.1 |

| China Invention Patent | A preparation method of high thermal conductivity graphite paper | 201310628887.4 |

| China Invention Patent | A preparation method of nanosilicon composite thermally conductive material | 201410100028.2 |

| China Invention Patent | An efficient continuous large-area preparation method of thermally conductive graphene | 201510540901.4 |

| China Invention Patent | A preparation method of anti-ultraviolet pigment and the pigment obtained from its preparation | 201910018125.X |

| China Invention Patent | A water-based graphene anticorrosive heat insulation coating and its preparation method | 201910276555.1 |

| Utility Model Patent | A kind of multi-purpose combined heating pad | 201920208444.2 |

| Utility Model Patent | A flexible graphene heating device that can be used for localized heating of crops | 201920545901.7 |

| Utility Model Patent | A new type of low pressure graphene electric heating film | 202121310392.3 |

Graphene is an all-purpose additive that can be used in a wide range of applications to significantly enhance performance

Our Graphene Preparation Technology

Physical methods of graphene preparation

Chemical methods of graphene preparation

Hybrid methods of graphene preparation

Research techniques for the functionalization modification of graphene

Technologies for dispersing graphene in various media

Dozens of functionalized graphene product technologies

Thermal management materials development

Conductive material development capability

R&D and manufacturing of special fiber material

Pass TUV, SGS, CE Certificated

Contact Form

Leave Us A Message

We have advanced preparation technology and scientific researchers, we can produce special graphene material according to your needs.