Are Low-Voltage Electric Blankets Safe

Are Low-Voltage Electric Blankets Safe? Here’s The Shockingly Simple Truth Winter’s coming, and you’re relying on that electric blanket to survive – but is sleeping

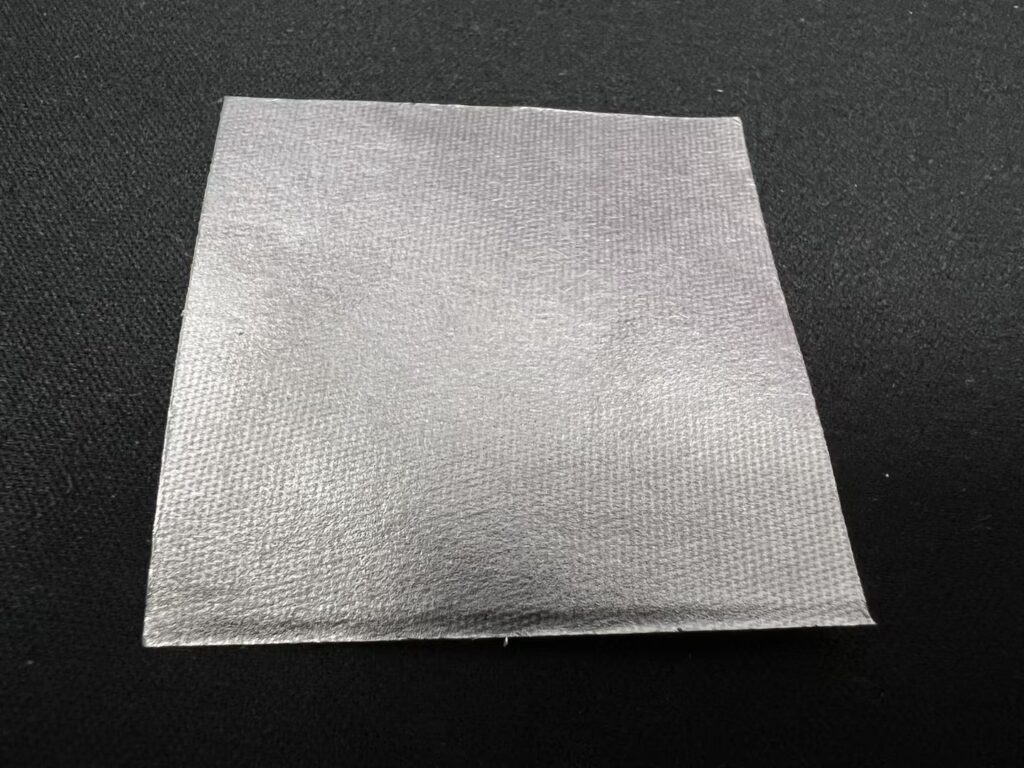

Alright, so you’ve got a graphene sheet in your hands—or you’re thinking about getting one—but you’re probably wondering, “How on earth was this tiny wonder actually made?” Don’t worry, I’m here to break down the magic of graphene production in the simplest way possible. Let’s dive into how this super-thin, super-strong, and super-light material is crafted, layer by layer.

Table of Contents

Toggle

Graphene is essentially a single layer of carbon atoms arranged in a hexagonal pattern (think of it like a honeycomb). Even though it’s just one atom thick, graphene is incredibly strong, super flexible, and conducts electricity like nobody’s business. This makes it perfect for all sorts of futuristic uses, from electronics to medical devices, and even aerospace technology!

Graphene is essentially a single layer of carbon atoms arranged in a hexagonal pattern (think of it like a honeycomb). Even though it’s just one atom thick, graphene is incredibly strong, super flexible, and conducts electricity like nobody’s business. This makes it perfect for all sorts of futuristic uses, from electronics to medical devices, and even aerospace technology!

Every graphene sheet starts with a humble source of carbon. This can be anything from graphite (yes, the same stuff in pencils) to even organic materials like sugar! The most common approach uses graphite because it’s easy to process and contains plenty of carbon.

Exfoliation – Remember when you’d accidentally peel a sticker just right, and it would split into thin layers? Exfoliation works a bit like that. With exfoliation, scientists start with a chunk of graphite and peel it layer by layer until they get down to a single layer of carbon atoms. This is how the first-ever graphene sheet was made—someone literally used Scotch tape to peel off graphite layers until they were left with just one. It’s great for labs but not practical for making bulk graphene.

Chemical Vapor Deposition (CVD) – This is the high-tech, commercial way to make graphene sheets. First, scientists put a thin layer of metal (usually copper) in a special chamber. Then, they pump in a gas that contains carbon (like methane) and heat it up to super high temperatures. At this point, the carbon atoms start sticking to the copper layer, arranging themselves in that magical hexagonal pattern to form a sheet of graphene. Once the graphene forms, the copper is carefully removed, leaving a pure graphene sheet. Ta-da!

Now that we’ve got our beautiful sheet of graphene, it’s time to move it onto the material where it’s actually going to be used. This transfer process needs to be done with extreme care—after all, we’re dealing with something only one atom thick! The graphene is gently lifted from its original copper layer and placed on the final surface, whether it’s glass, plastic, or silicon.

Once the sheet is ready, it goes through some serious quality control. Graphene needs to be as flawless as possible, so scientists check it under special microscopes to make sure there aren’t any gaps or wrinkles. High-quality graphene has no breaks in its structure, ensuring that it maintains its incredible strength and conductivity.

If you’re getting a graphene sheet, knowing how it’s made helps you appreciate the level of care and science that goes into creating this “wonder material.” From exfoliating down to the last layer of carbon to using CVD for smooth sheets, every step matters in getting you a reliable, high-quality sheet of graphene.

There you have it: your graphene sheet, ready to take on whatever project you have in mind. Whether it’s for electronics, a fancy sensor, or just because it’s cool (because, honestly, who wouldn’t want to own a sheet of graphene?), you now know the science behind its creation. Simple, right?

And speaking of graphene, let me introduce us! We’re one of China’s leading graphene sheet manufacturers, known for **high-volume, low-cost production** without compromising on quality. Our process is backed by **multiple patents**, ensuring that every sheet we make meets the highest industry standards. Whether you’re looking for bulk orders or specific customizations, we’re here to provide you with top-quality graphene sheets tailored to your needs. Ready to bring a bit of the future to your projects? We’ve got you covered. More About Us

We produce and develop graphene raw materials and graphene applications, with 50 researchers, and are open to working with you to develop customized products.

Are Low-Voltage Electric Blankets Safe? Here’s The Shockingly Simple Truth Winter’s coming, and you’re relying on that electric blanket to survive – but is sleeping

Winter’s back, and getting into bed feels like climbing into a freezer. As someone who’s always cold, an electric blanket is my survival tool. But

TL;DR: Y’all, heating tech just got a major glow-up. Graphene blankets aren’t just another product—they’re a total game-changer. We’re talking next-level warmth, wellness-based design, and

Traditional electric blankets can cause dryness and dehydration with prolonged use. Why do graphene electric heating blankets feel less dry and are more comfortable? You’ve

Experience the excellent energy-saving underfloor heating brought by new technology

We’ll get back to you in 1 business day.