Are low emf electric blankets necessary?

Another chilly winter has arrived, and electric blankets have become lifesavers for many. But every year around this time, concerns resurface: Can the electromagnetic fields

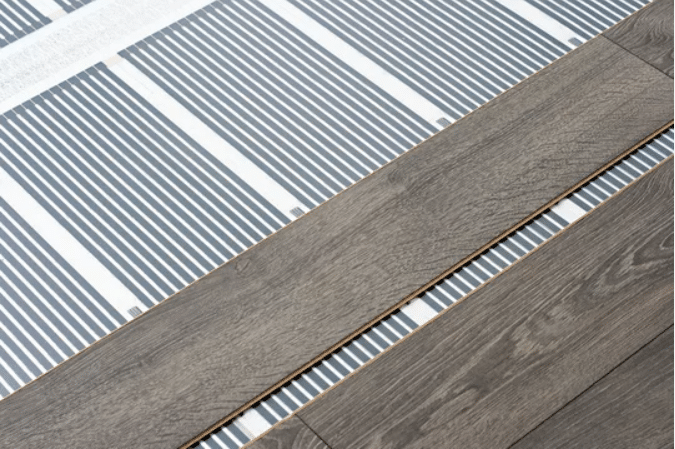

Underfloor heating film is a film that generates heat when electricity is applied to it. underfloor heating film usually consists of a flat heating element made of an electrical insulating material encapsulated with a heat-generating resistive material, which can be applied to ceramic tiles, wooden floors, etc., to provide comfortable temperatures in indoor spaces. underfloor heating film’s electrical insulating material is mostly similar, but has different properties due to the different heat-generating resistive materials. However, due to the different heating resistance materials, different properties are formed.

Table of Contents

Toggle

The traditional resistance wire heating film is used in the insulating material inside the resistance wire, so that the current through the resistance wire after power generation to produce heat. The traditional resistance wire heating film has uneven heating, local temperature is too high leading to scalding, low electric heat conversion rate and other shortcomings, at the same time, if the resistance wire breaks may lead to leakage of such serious consequences, so now the resistance wire underfloor heating film has been mostly replaced by other underfloor heating film. So now the resistance wire underfloor heating film has been mostly replaced by other underfloor heating film.

Carbon fibre is a kind of fibre material with carbon content above 95%. Carbon fibre material is generally produced by flake graphite microcrystalline and other organic fibres stacked along the axial direction of the fibre, carbonized and graphitized microcrystalline graphite material. carbon fiber underfloor heating film of the heat resistance material is made of polythinyl nitrile and viscose-based carbon fibre composite by a special process. It has the advantages of light weight, soft, and good fit with human body. However, it has the disadvantages of poor safety, easy to burn, easy to break the internal fibre filaments, uneven temperature, etc., which can easily cause safety accidents and is more dangerous.

Carbon crystal is a kind of plate made by using carbon particles or short carbon fibres as heat generating resistive material, and then adding adhesive to press it. Because of its production process, the material is easy to aging, thermal efficiency attenuation is serious, resulting in the service life is not long, and carbon particles and adhesives are easy to delamination, thus producing harmful gases, so the use of less.

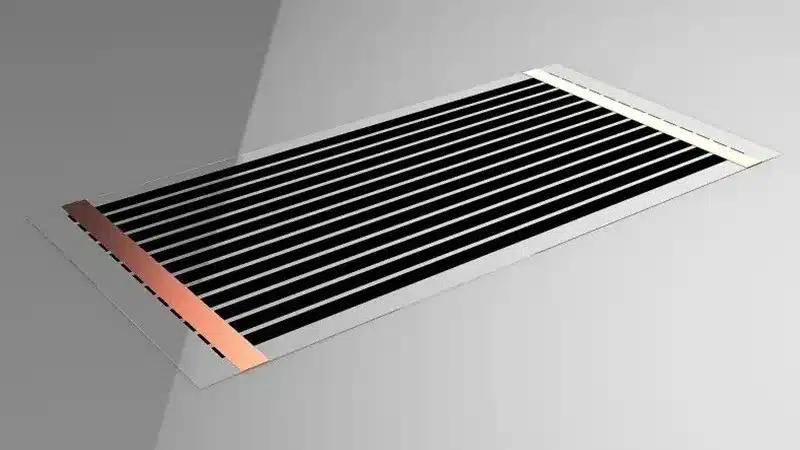

Carbon-based ink-based underfloor heating film, its heating principle is graphite, carbon particles, metal oxides and other materials with other filler materials together to create an ink-like printing paste. Then screen printing process quantitative printing in advance bonded metal carrier strip (as the electrode) polyester film, and then covered with polyester film to form an insulating structure, it is also known as printing ink electric heating film. The power control of this type of electric heating film is mainly achieved through the composition of the paste, the thickness and spacing of the ink strip. Its disadvantage is that the internal paste is easy to crack, not acid and alkali resistance, voltage breakdown and combustion risk.

What is graphene heating film, graphene electric heating film’s thermal conductive material is graphene. Graphene is a two-dimensional material consisting of a single layer of carbon atoms, and is considered a “wonder material” because of its unique crystal structure and electronic properties. It has extremely high thermal and electrical conductivity, which means that it can quickly convert electrical energy into thermal energy in electric heating applications. In addition, graphene is flexible, stable and biocompatible.

due to the high electrical and thermal conductivity of graphene, graphene underfloor heating film generates heat quickly and distributes it evenly. This enables graphene underfloor heating film to provide higher temperature in the same time, thus improving the heating efficiency.

Graphene is chemically stable and not easily oxidised or degraded. This makes the service life of graphene electric heating film greatly exceeds that of ordinary electric heating film, reducing the frequency of replacement and the cost of maintenance.

Graphene electric heating film has a high electrical energy conversion efficiency and low electrical energy loss, thus achieving energy saving. At the same time, the use of graphene electric heating film also contributes to environmental protection as graphene is derived from graphite, which is a sustainable resource.

Because graphene electric heating film can precisely control the temperature, making the heating more uniform, people can feel more comfortable temperature in the process of use.

Graphene electric heating film has good flexibility and can be easily applied to surfaces of various shapes and sizes, which makes it have a wide range of applications in the fields of heating, medical treatment, aerospace and so on.

the thermal efficiency of ordinary electric heating film is low, and there will be more energy loss in the process of converting electric energy into heat energy.

ordinary electric heating film in the process of long-term use, due to the thermal expansion and oxidation of the resistance wire, easy to fracture, aging and other problems, resulting in shorter service life.

ordinary electric heating film in the temperature control has certain limitations, easy to appear too high or too low temperature.

ordinary electric heating film due to material and performance limitations, the application range is relatively narrow, difficult to meet the diverse needs.

In summary, when Australian homeowners ask, “Do heated floors use a lot of electricity in Australia?”, the answer varies with the type of underfloor heating chosen. Traditional cable systems, though effective, are less energy-efficient than their graphene counterparts. For those looking to make an environmentally responsible decision that aligns with long-term savings, graphene underfloor heating stands out as the superior option. It is an investment in comfort, efficiency, and the well-being of our planet. As Australia continues to move toward renewable energy sources and energy-efficient technologies, graphene underfloor heating can play a pivotal role in this transition, ensuring warm toes and a cool planet for future generations.

Another chilly winter has arrived, and electric blankets have become lifesavers for many. But every year around this time, concerns resurface: Can the electromagnetic fields

Are Low-Voltage Electric Blankets Safe? Here’s The Shockingly Simple Truth Winter’s coming, and you’re relying on that electric blanket to survive – but is sleeping

Winter’s back, and getting into bed feels like climbing into a freezer. As someone who’s always cold, an electric blanket is my survival tool. But

TL;DR: Y’all, heating tech just got a major glow-up. Graphene blankets aren’t just another product—they’re a total game-changer. We’re talking next-level warmth, wellness-based design, and

Experience the excellent energy-saving underfloor heating brought by new technology

We’ll get back to you in 1 business day.