Are Low-Voltage Electric Blankets Safe

Are Low-Voltage Electric Blankets Safe? Here’s The Shockingly Simple Truth Winter’s coming, and you’re relying on that electric blanket to survive – but is sleeping

This article will tell you what is graphene heating film; the Characteristics of Graphene Heating film; the Heating principle of Graphene Heating film; graphene heating film VS other types of Heating film.

Table of Contents

ToggleGraphene heating film is a composite film that can generate heat after being electrified. It is made of a conductive composite film composed of highly conductive graphene and polyester, equipped with a current carrying strip, and then covered with an insulation protection layer. It uses graphene powder, a superconductive material, to produce heat in the form of far-infrared radiation and convection. They can be installed after processing on floors, walls, or ceilings to provide low-temperature radiant heating.

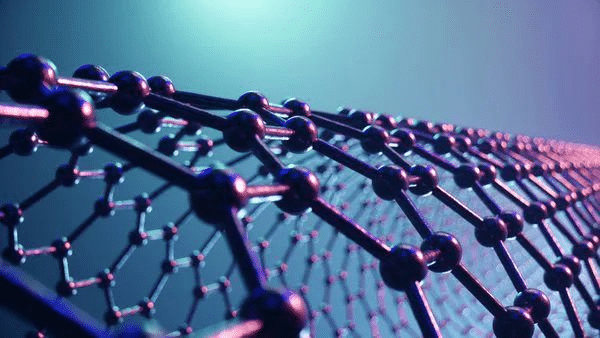

Graphene heating film uses a two-dimensional Network of covalent bonding Graphene to heat. Graphene is a dense layer of carbon atoms wrapped in a honeycomb crystal lattice, with a thickness of only 0.34 nm. Graphene has many excellent characteristics, such as high mechanical strength (Young’s modulus up to 1TPa), good conductivity (resistivity only 10-6 Ω. cm), thermal conductivity (thermal conductivity up to 5300W/m.K), high Saturation current density (can withstand a current of 100-200 million A/cm2) and large specific surface area (theoretical as high as 2630m2/g). The heating film made of Graphene has the advantages of fast heating, fast heat dissipation, and good stability.

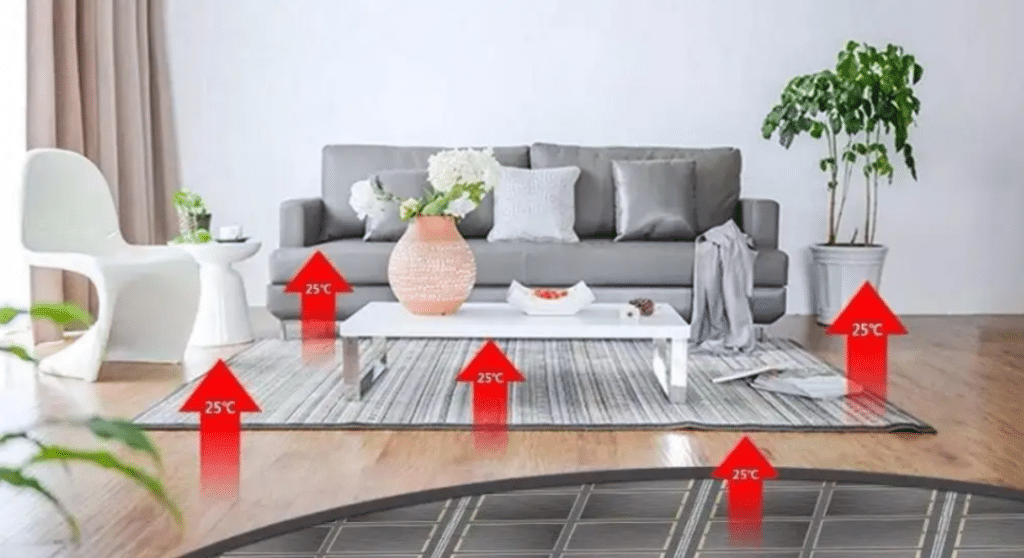

The Graphene Heating film heats up quickly, the temperature is stable, and the heat from bottom to top forms a temperature gradient, which can ensure that the temperature is sufficient and the top is cool, the temperature and humidity are maintained in the most suitable range for the human body, and the Graphene Heating film can emit (3-15 μ m) The far-infrared light wave has far-infrared therapeutic effects, which can improve blood circulation and promote metabolism.

After two or even one year’s use of ordinary electric floor heating, it can be clearly felt that the heat attenuation is extremely serious, and the power consumption is several times that of the previous year. However, the attenuation of traditional water heating also exists, but the attenuation of traditional water heating is related to the quality of water heating pipes and sediments. The water heating needs to clean the pipes regularly every year. Graphene itself has good stability, and it will hardly cause heat attenuation after use. It can be used for 50-70 years, almost the same lifespan as the building.

The electrothermal conversion rate of Graphene Heating film is more than 99%, far higher than that of ordinary floor heating products. In short, under the same power input, electric floor heating with Graphene can convert 99% of the heat, and ordinary floor heating products can also convert 70% of the heat. Compared with the centralized control of traditional water heating, the independent control of the time-sharing room of Graphene Heating film floor heating can save more energy and at least 30% of the cost.

Electric floor heating belongs to Far infrared temperature radiation heating. Especially when electric floor heating is running, it will not give people a sense of dryness and heat. The indoor temperature decreases from bottom to top layer by layer. Warm feet and cool the roof, and warm feet can accelerate blood circulation throughout the body to ensure timely supply of body nutrients. And the head temperature is moderate, so staying for a long time won’t make you feel dizzy and hot. In addition, the way of heating by Far infrared radiation has certain physiotherapeutic effects on human health care, which can effectively promote blood circulation, accelerate metabolism, improve muscle soreness, and benefit human health.

Graphene is a hexagonal honeycomb single-layer carbon atomic material separated from graphite materials, and its thickness is only 0.335 nm. Graphene electric floor heating mainly relies on Graphene Heating film for heating. In short, after power on, the electrons in the current flow through Graphene heating film, collide and rub with carbon atoms in Graphene Heating film to generate heat, which is then transmitted to the human body through far-infrared radiation.

Graphene is a new carbon material with carbon atoms tightly packed into a single-layer two-dimensional honeycomb lattice structure. Its thickness is only 0.335 nm, only 200000 times that of hair. It is the basic unit for building other dimensional carbon materials (such as zero-dimensional Fullerene, one-dimensional carbon nanotubes, and three-dimensional graphite), and has excellent crystallinity, mechanical properties, and electrical quality.

Graphene is not a metal, but a carbon family non-metallic element, but has good conductivity, mainly due to the unique stable molecular structure of Graphene.

Graphene has very good thermal conductivity. The thermal conductivity of pure defect-free single-layer Graphene is up to 5300W/mK, which is the highest carbon material by far. At the same time, the structure of Graphene is also very stable, and the carbon-carbon bond is only 1.42. The connection between the carbon atoms inside Graphene is very flexible. When an external force is applied to Graphene, the surface of the carbon atoms will bend and deform, so that the carbon atoms do not have to be rearranged to adapt to the external force, so as to keep the structure stable. This stable lattice structure makes Graphene have excellent thermal conductivity. In addition, when the electrons in Graphene move in the orbit, they will not scatter due to lattice defects or the introduction of foreign atoms. Because of the strong interatomic force, at room temperature, even if the surrounding carbon atoms collide, the interference to the internal electrons of Graphene is very small.

After the Graphene Heating film is powered on, it radiates heat through the far-infrared form. Generally, the wavelength of the far-infrared of the Graphene Heating film is 5-12um, which can just be absorbed by the human body to provide heat for the human body and provide heat for the room. Its electrothermal conversion rate is up to 99%, which is far higher than other electrical appliances.

According to different heat generators, low-temperature radiation Heating film can be divided into three categories: metal-based Heating film, inorganic non-metallic based Heating film, and polymer Heating film. Among them, the inorganic non-metallic Heating film can be divided into “carbon-based ink Heating film” and “carbon fiber Heating film”. We investigated the vast majority of products in the market, 99% of the Heating film, nothing more than metal wire Heating film, carbon fiber Heating film, carbon crystal plate Heating film, PTC ceramic Heating film, carbon-based ink Heating film, and Graphene heating film.

1. Directly prepare the film on the heated carrier, for example, by mixing conductive and film-forming substances into a slurry, coating it on the object to be heated, drying, and pyrolysis spraying to form a film; Such as carbon-based ink Heating film.

2. The Heating film is elementwise, for example, the conductive material and the film-forming material are mixed and extruded; Such as carbon fiber/carbon crystal plate Heating film.

3. Chemical/Physical vapor deposition, vacuum spraying, ion sputtering, screen printing, and other methods are used to integrate the conductive material and the film substrate; Such as Graphene Heating film, and carbon-based ink Heating film.

1. Poor safety and easy to burn

2. Internal fibers are prone to breakage

3. Temperature imbalance, difficult to control

4. Not waterproof

5. Not resistant to acid and alkali

6. Poor creep resistance

Carbon fiber is a fiber material with a carbon content of over 95%. It is a microcrystalline graphite material obtained by stacking organic fibers such as flake graphite microcrystals along the axial direction of the fibers and undergoing carbonization and graphitization treatment. The heating substrate of the carbon fiber heating body is composed of polyacrylonitrile and viscose-based carbon fibers through special processes. Its advantages are light weight, softness, and a good fit with the human body. But the drawbacks are very obvious, and the safety accidents caused by it can be said to be palpitating.

1. Easy to age, severe thermal efficiency degradation

2. Carbon particles and adhesives are prone to delamination

3. Release of harmful gases

4. Risk of voltage breakdown and leakage

5. Short lifespan

Carbon crystals, first of all, please do not confuse them with materials such as liquid crystals. There is no such material as carbon crystal in the world, and there is no such term in technical terminology. Carbon crystal is just a term used by businesses to confuse right and wrong. Simply put, carbon crystal products are a type of board made by pressing carbon particles or short carbon fibers as conductive materials with adhesive. This kind of Heating film has been controversial for a long time since it came into the market. Its durability is also being tested.

1. Release of harmful substances

2. Prone to cracking

3. Bubbling causes detachment of the insulation layer

4. Not resistant to acid and alkali

5. Risk of voltage breakdown and combustion

Carbon-based ink type Heating film, heating materials are graphite, carbon particles, metal oxides, etc. The production process of carbon-based ink Heating film is to make the above heating materials and other fillers into an ink-like slurry, quantitatively print them on the polyester film pre-bonded with metal current carrying strips (as electrodes) by screen printing process, and then cover the polyester film to form an insulation structure, so it is also called printing ink Heating film. The power control of this kind of Heating film is mainly realized by slurry composition, ink stripe thickness, and spacing. Due to the influence of Graphene’s heat, some businesses will adulterate a small amount of Graphene powder or slurry when preparing this Heating film to render the concept of Graphene Heating film.

1. Safe and environmentally friendly, noncombustible

2. Long lifespan, less prone to aging

3. Balanced temperature surface, easy to control

4. Waterproof and corrosion-resistant

5. Good pressure and weather resistance

6. Good stability

Graphene is a single-layer carbon atom, which is characterized by stability and safety. The electrothermal conversion efficiency is the highest among all electric heating elements or the highest in parallel. There is almost no other form of energy loss in the energy conversion process, such as mechanical energy, light energy, Chemical energy, etc., and the electrothermal conversion efficiency is close to 100%. Among them, the ratio of electric thermal radiation conversion efficiency is also the larger among electric heating components with the same unit area power.

It is worth noting that with the full display of Graphene material advantages, some of the hyped Graphene film products in the market are the films formed by the oxidation of graphite, or some of the Heating film prepared by mixing a small amount of Graphene powder, expanded graphite and graphite chips have become the hardest hit areas of the pseudo graphite concept and capital hype. The result is that the product quality in the market is unstable and there are various potential safety hazards, This is not because Graphene material itself is not good, but because some enterprises are eager for quick success and instant benefit when using Graphene, ignoring consumer rights and interests, which will lead to consumers’ misjudgment of Graphene material over time, and also bring negative impact on the development of Graphene industry. At the initial stage of the development of the Graphene industry, enterprises with a sense of responsibility are required to make good products and applications, treat the Graphene industry more practically, and strive for perfection to create products!

Are Low-Voltage Electric Blankets Safe? Here’s The Shockingly Simple Truth Winter’s coming, and you’re relying on that electric blanket to survive – but is sleeping

Winter’s back, and getting into bed feels like climbing into a freezer. As someone who’s always cold, an electric blanket is my survival tool. But

TL;DR: Y’all, heating tech just got a major glow-up. Graphene blankets aren’t just another product—they’re a total game-changer. We’re talking next-level warmth, wellness-based design, and

Traditional electric blankets can cause dryness and dehydration with prolonged use. Why do graphene electric heating blankets feel less dry and are more comfortable? You’ve

Experience the excellent energy-saving underfloor heating brought by new technology

We’ll get back to you in 1 business day.